CGI, ThyssenKrupp Elevator and Microsoft – Launching their IoT-based Predictive Maintenance Solution

Following the recent announcement of the initial commercial implementation of Microsoft’s Intelligent Systems Solution (ISS) for Telent on 15 April at the launch event in San Francisco, USA, CGI and Microsoft have again joined forces to support ThyssenKrupp Elevator to deliver a game-changing predictive maintenance solution for more than 1.1m elevators under maintenance worldwide.

Elevator reliability is a key differentiator for ThyssenKrupp Elevator and the connected, intelligent line-of-business (LOB) asset monitoring system being implemented will take this and safety to new levels.

By connecting elevators to the cloud, gathering data from sensors and systems, and transforming that data into valuable business intelligence, ThyssenKrupp is vastly improving its maintenance services.

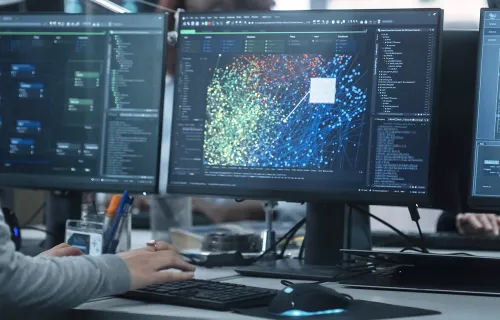

CGI developed a solution that securely connects ThyssenKrupp’s “things” - the thousands of sensors and systems in its elevators that monitor everything from motor temperature to shaft alignment, cab speed and door functioning; the data they gather; and PCs and mobile devices used by its workforce of technicians - to the cloud with Microsoft Azure Intelligent Systems Service.

Now, instead of just reacting to a failure alarm, technicians can use real-time data to define a required repair even before a breakdown occurs. In addition, thanks to a two-way flow of data, technicians can remotely put an elevator into diagnostics mode, or send it to another floor. It all adds up to less travel time, better efficiency, and reduced costs.

“We wanted to go beyond the industry standard of preventative maintenance, to offer predictive and even pre-emptive maintenance, thereby guaranteeing a higher uptime percentage on our elevators,” says Andreas Schierenbeck, ThyssenKrupp Elevator CEO.

Contact us to find out more and speak to an expert or visit our Internet of Things page.