At CGI, we have strong collaborations with universities and academic institutions worldwide to drive forward innovation and research and help inspire the next generation of IT professionals. In the Netherlands, we have partnered with the Fraunhofer Innovation Platform for Advanced Manufacturing at the University of Twente to work together on innovative data-driven projects in manufacturing.

In this recent article published in the InnovatieNu 07 / Fraunhofer Innovation Platform, a university publication, CGI’s Fokke van Houten, Director, Consulting Expert in Asset Performance Management & Maintenance, discusses the intersection of people, technology and manufacturing and the future of the manufacturing workplace.

How is the digital transformation within manufacturing affecting the industry’s workforce? The implications could be more far-reaching than suspected.

How can manufacturers anticipate this?

Digitization is a top priority for the industry. Why? Because of continuously changing customer demand and increasing expectations for product diversity, quality, safety and sustainability. This requires efficient, effective and adaptive manufacturing processes.

Transformation to a desirable level of digitization is a major challenge for many manufacturers. The phased and structured implementation of new technologies in the production domain that both fit the needs of the current situation and also contribute to desirable professionalism is challenging enough.

The human factor plays an important role within manufacturing processes today and will continue to do so for the foreseeable future. Of course, the playing field is changing, and a digitized production environment places different demands on workers in terms of knowledge and skill levels, but people will continue to be indispensable for manufacturers and production companies.

The human factor plays an important role within manufacturing processes today and will continue to do so for the foreseeable future.

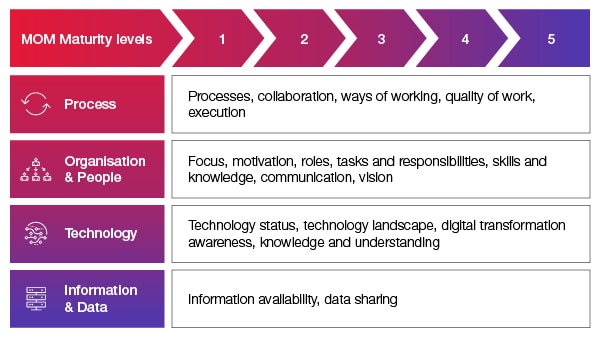

Digitization of the production domain calls for focusing on all POTI aspects (Process, Organization & People, Technology, and Information & Data). This article focuses on the organizational and people aspect.

What are the key workforce-related developments in manufacturing?

Aging workforce

Over the past decade, the workforce, measured by people between the ages of 15 to 75, has grown by more than half a million. This will decrease to only 130,000 people in the next 10 years. The effect of a higher retirement age is minimal. This means that the number of people between the ages of 15 and 75 will also continue to decrease. At the same time, the proportion of older people within the workforce is increasing. In general, older workers work less often and also fewer hours per week. Whether this aging will lead to a shortage of workers depends on the number of people working, the number of hours that people work and labor productivity needs versus actual labor productivity. (source CBS).

Digital transformation of the production domain will not result so much in higher labor productivity, but rather in higher labor efficiency and effectiveness. In other words: the ability to achieve the same production with less labor. But does that fully mitigate the adverse effects of aging? Digitization of the production domain requires significant investment that will have to show returns, leading to pressure on the revenue model. A possible consequence is a need to produce more which again increases the need for people.

Digital transformation of the production domain will not result so much in higher labor productivity, but rather in higher labor efficiency and effectiveness.

Tight labor market

Currently, the labor market is already tight. One of the implications for employers is the challenge of remaining relevant and interesting enough for the current population of employees. With the departure of employees, a lot of knowledge and experience often walks out the door, leading to capacity challenges and jeopardizing competitiveness. So, it is essential to retain existing employees. We see that turnover is relatively low in companies that continuously pay attention to employee well-being.

However, employee well-being is not only influenced by primary and secondary benefits. Paying attention to the person behind the employee and their needs is also important. A sufficiently challenging role aligned with the employee’s needs and capacity, including associated tasks and responsibilities, keeps motivation and commitment high. This is exactly why the human factor is an integral part of change. Fortunately, digital transformation offers plenty of opportunities for employees to advance to appropriate and challenging roles.

A sufficiently challenging role aligned with the employee’s needs and capacity, including associated tasks and responsibilities, keeps motivation and commitment high.

Need for knowledge retention and development

A higher degree of digitization within production requires personnel with a higher level of knowledge and competence. This does not necessarily mean different personnel, but it does mean that continued development of the skill and knowledge level of the current workforce should be high on the agenda of manufacturing companies. There will have to be a shift to a different type of workforce as the production environment continues to digitize. It is crucial to ensure the right balance between the “maturity” of the production environment and the duties and responsibilities of employees. A clear and concrete transition plan for digital production maturity helps tremendously in this regard.

Focusing on the recruitment of new employees remains as important as ever. More and more manufacturing companies are looking to connect with colleges and universities to inspire students about jobs within manufacturing. When students are involved early on in the process of digital transformation at manufacturing companies and make a significant contribution, it increases the likelihood of employers hiring thereafter.

Manufacturing companies lose valuable knowledge when employees leave and are trying to secure this knowledge in various ways. Digital transformation offers opportunities and solutions for this as well. Examples range from basic solutions such as securing knowledge using processes, flow charts and instructional videos. Similar solutions are often found in manufacturing companies that are still relatively low on the maturity ladder. We also increasingly see manufacturers securing valuable process knowledge using digital twins, machine learning and artificial intelligence—a positive outcome of the growth in digital maturity. Thus, by recording important process actions and events by employees, valuable information is retained by manufacturing companies.

It is crucial to ensure the right balance between the “maturity” of the production environment and the duties and responsibilities of employees. A clear and concrete transition plan for digital production maturity helps tremendously in this regard.

Key takeaways

Digital transformation is a must for manufacturing companies. On the one hand, to respond to rapidly changing market dynamics to maintain a competitive position and, on the other hand, to increase workforce productivity to compensate for the tightness in the labor market, partly due to an aging population.

Digital transformation is not just about technology and data. A clear and concrete transition plan for digital manufacturing maturity includes all four POTI aspects and guarantees the necessary focus on the organization and employees. A phased approach consistent with the organization’s vision and strategy will provide solutions in the area of knowledge retention and development.